| Category | Products Capacity |

| Title | 07. What is the most suitable range of Acc/Dec in case of using FASTECH product selection program? |

|

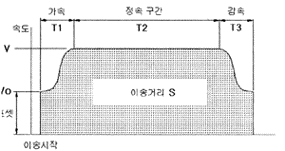

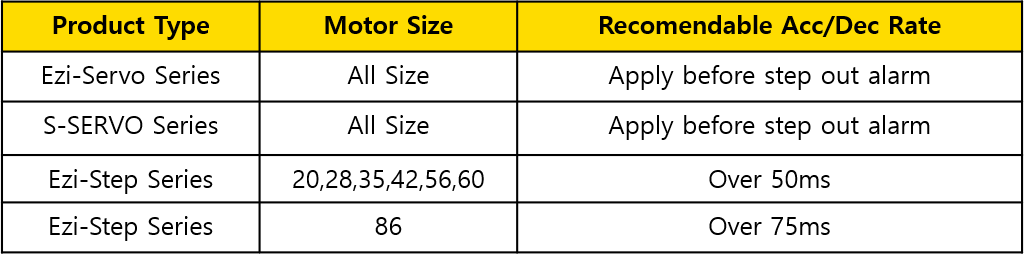

In general, 20% of the in-position time is appropriate. But there is some difference between each equipment, so please try to find out the most appropriate Acc/Dec value. Acc/Dec setting is one of the key factors to control machines. If Acc/Dec value is too short, it will impact the life cycle of machines and robots due to vibration. Also if Acc/Dec value is too long, overall productivity will be decreased due to Tack Time delay. So please try to find out the most appropriate Acc/Dec value depending on facilities. Also load, there are friction load, inertia load and other external force(gravity) and especially inertia moment will be proportional to the ration of Acc/Dec. If inertia load goes high, will be difficult to be immediately accelerated or decelerated and also the operational capacity of the motor should be very high to shorten the time of Acc/Dec. The sudden deceleration can be a reason for over regenerative voltage error. In this case, please the loose time of deceleration. As a result, please select an appropriate motor according to load and motion condition. And FASTECH supports customers to select the right size of the motor, especially from our website. For more details, please contact with FASTECH sales team. (http://www.fastech.co.kr/ → SUPPORT → Motor Selection Guide )

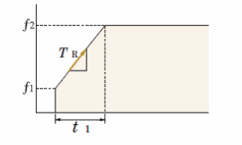

following formula as below. Acc/Dec Rate T R = Acc(Dec) Time (ms) ,

<General Curve of Step Motor Motion Control>

|

|

| Files | 200115_FAQ07_ENG.pdf |

| List |